Sleipner—A Carbon Dioxide Capture-and-Storage Project

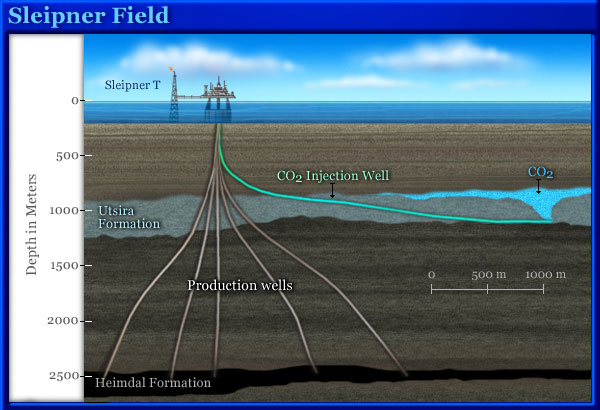

The Sleipner field is in the North Sea, about 250 km (155 mi) west of Stavanger, Norway. It is operated by Statoil, Norway’s largest oil company. The Sleipner field produces natural gas and condensate (light oil) from the Heimdal sandstones, which are about 2,500 m (8,200 ft) below sea level.

Natural gas is a mixture of gases. It is typically at least 90% methane, plus other hydrocarbons such as ethane and propane. Natural gas often also contains gases such as nitrogen, oxygen, and carbon dioxide; sulfur compounds; and water. Gas containing small volumes of these impurities can still be used as fuel, but gas with high volumes of them cannot be burned efficiently and safely.

The natural gas produced at Sleipner contains unusually high levels (about 9%) of carbon dioxide (CO2), but the customers buying the gas from Statoil need less than 2.5%.

A special platform, Sleipner-T, has been built to support a 20-m-high (65-ft), 8,000-ton treatment plant that separates CO2 from the natural gas. The Sleipner-T plant produces about 1 million tons of CO2 per year.

To encourage companies to reduce their carbon emissions, the Norwegian government imposes a carbon tax equivalent to about $50 per ton of CO2 released into the atmosphere. To avoid paying this tax, and as a test of alternative technology, all of the CO2 extracted since 1996, when gas production started at Sleipner, has been pumped back deep underground.

It is not put back where it came from, because that would further contaminate the natural gas. Instead, it is put into a 200-m-thick (650-ft) sandstone layer called the Utsira formation, about 800 m (2,600 ft) beneath the bottom of the North Sea. The Utsira formation contains no commercial oil or gas; like most rocks deep underground, it is filled with salt water. The Utsira formation has high porosity and permeability, so the CO2 moves rapidly sideways and upward through the rock layer, replacing the water between the sand grains.

It is estimated that it would take about 600 billion tons of CO2 to fill all the pore space of the Utsira sandstone. That is equivalent to all the human-made CO2 production for over 20 years, at current rates. It is likely that CO2 sequestration will continue at Sleipner long after the abandonment of the field as a hydrocarbon producer. The Utsira formation is just one of many similar deep saline aquifers around the world that could be used to help slow down or reverse the rate at which CO2 and other greenhouse gases are released into the atmosphere.

The Sleipner project is the first commercial example of CO2 storage in a deep saline aquifer, so there is a lot of interest from around the world in its success. In particular, scientists want to know how the CO2 moves inside the aquifer and if there is a risk that it could escape back to the surface.

Another CO2 capture-and -storage project is in the Weyburn field in Canada.

This content has been re-published with permission from SEED. Copyright © 2025 Schlumberger Excellence in Education Development (SEED), Inc.