The Many Roles of Drilling Fluids

The harsh environment in underground drilling operations encouraged the research and development of drilling fluids that can fill several crucial roles in the drilling process: suspension, pressure control, stabilization of formations, buoyancy, and lubrication and cooling.

Suspension

The flow of drilling fluid down the drill pipe and up the borehole sometimes stops, either because of a problem or in order to raise the drill pipe up and out of the hole to allow the bit to be changed. When drilling stops the cuttings suspended in the fluid can sink to the bottom of the hole and jam the drill. Drilling fluids are designed to have a very interesting property that takes care of this problem. The thickness, or viscosity, of the fluid increases as movement of the fluid slows. When the fluid stops moving it forms a thick gel that suspends the rock cuttings and keeps them from sinking to the bottom of the borehole. When the fluid starts moving again it becomes thinner and reverts to its previous thin, liquid form.

|

|

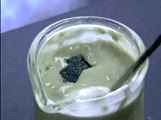

Visplex* has an interesting and unusual property. It can change form—from thick to thin. This allows the drilling fluid to suspend cuttings when drilling stops. |

|

||

|

At rest Visplex is a gel that supports the weight of the small rock shown here. |

When stirred it becomes more liquid and the rock sinks. |

|||

|

Pieces of rock are scraped free by the rotating drill bit. Drilling fluid is pumped down the drill pipe, picks up these cuttings and brings them to the surface. |

Pressure Control

There is a popular image of oil gushing from a rig, high into the sky, while workers rejoice at having found oil. Actually, such blowouts are rare and no cause for celebration, since the goal is to extract the oil in a controlled manner. Mud is designed to prevent such accidents by counteracting the natural pressure of fluids in rock formations. A proper balance must be achieved in which the pressure of the drilling fluid against the walls of the borehole is enough to counter the pressure exerted both by rock formations and by oil or gas but not so much that it damages the well. If the weight of the drilling fluid is too great it could cause the rock to fracture and the drilling fluid would be lost into the ground.

The pressure of a liquid depends on its density. Weighting agents may be added to the drilling fluid to increase its density, and thus, the pressure it exerts on the walls of the borehole. The density of the liquid may be adjusted to meet the conditions in the well.

Stabilization of the Exposed Rock Formation

There are two phases of the drilling process. At first, drilling moves through rock that does not contain oil. The goal is to move as quickly as possible and get to the oil-bearing rock—the reservoir. The priority is on keeping stable the exposed rock formation in the borehole (which may contain water) while avoiding the loss of drilling fluid. Keeping the drilling fluid at a pressure that is higher than the fluid pressure from the pores within the rock formation can permit the drilling fluid to enter permeable rock in the formation. However, special additives in the drilling fluids can prevent this from happening.

The drilling fluid may interact with the surrounding rock in other ways. For example, if the rock is laden with salt, water will dissolve the salt. This tends to make the walls of the borehole unstable. It would be better to use an oil-based drilling fluid in this situation. Rock formations with a high clay content also may tend to be washed away by water. Such formations require an inhibitive fluid to maintain a stable wellbore and prevent enlargement, or washouts.

As drilling progresses, the wellbore is lined with a steel casing, which is cemented in place to provide both well bore stability and a route to the surface for oil when the reservoir is reached. After the drilling reaches the reservoir, the composition of the drilling fluid may have to be changed to avoid clogging the pores of the rock. Keeping the pores open will allow oil to flow more freely into the borehole and up to the surface.

Buoyancy

A well may be many thousands of meters or feet deep. A steel drill pipe of such great length is very heavy. Immersing the drill pipe in fluid produces a buoyancy effect, reducing its weight and putting less stress on the drilling mechanism.

Lubrication and Cooling

When metal moves against rock, friction and heat result. Drilling fluids provide lubrication and cooling to keep the process moving along smoothly—and to extend the life of the drill bit. Lubrication may be especially important on extended reach or horizontal wells where the friction between the drill pipe, drill bit and rock surfaces must be kept to a minimum.

This content has been re-published with permission from SEED. Copyright © 2025 Schlumberger Excellence in Education Development (SEED), Inc.